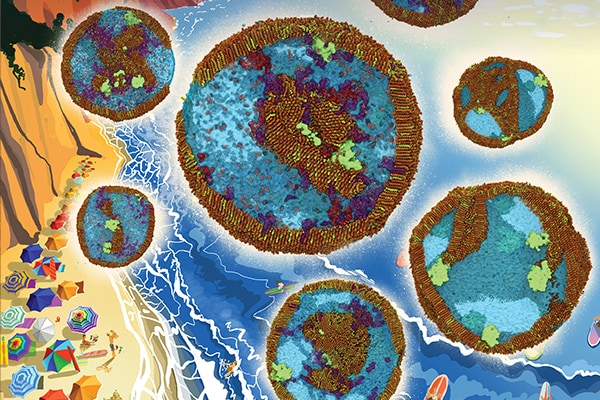

The need for effective antiviral countermeasures and the demand for personal protective equipment (PPE) have challenged the scientific community during the ongoing COVID-19 pandemic, but polymer chemists are working steadfast to aid this fight. Synthetic polymers are being designed to bind to a virus, blocking its ability to bind and infect cells. At the same time, several US government agencies have recommended the decontamination of filtering facepiece respirators (FFR) as a crisis strategy when PPE supply is exhausted. However, many decontamination methods can damage the polymers necessary for respirator fit and filtration making this process difficult.

Join experts Michael Schulz of Virginia Tech as he shares how antiviral polymers offer a promising approach to preventing and treating viral infections and Emilie Rexeisen of 3M for an overview of how 3M evaluated the impact of various decontamination procedures on the performance of 3M disposable FFR to aid healthcare facilities reuse PPE in times of emergency.

This ACS Webinar is moderated by Tomonori Saito of Oak Ridge National Laboratory (ORNL) and the University of Tennessee, Knoxville and co-produced with the ACS Division of Polymer Chemistry.

What You Will Learn

- How antiviral polymers were discovered, how the field has developed and what the future may hold for the field of antiviral materials

- What structural features give a polymer antiviral properties

- How four key aspects contribute to successful decontamination (decontamination efficacy, safety for the wearer, filtration efficiency, and respirator fit)

- How different respirator makes and models use different materials making it essential that each model is tested separately for each method